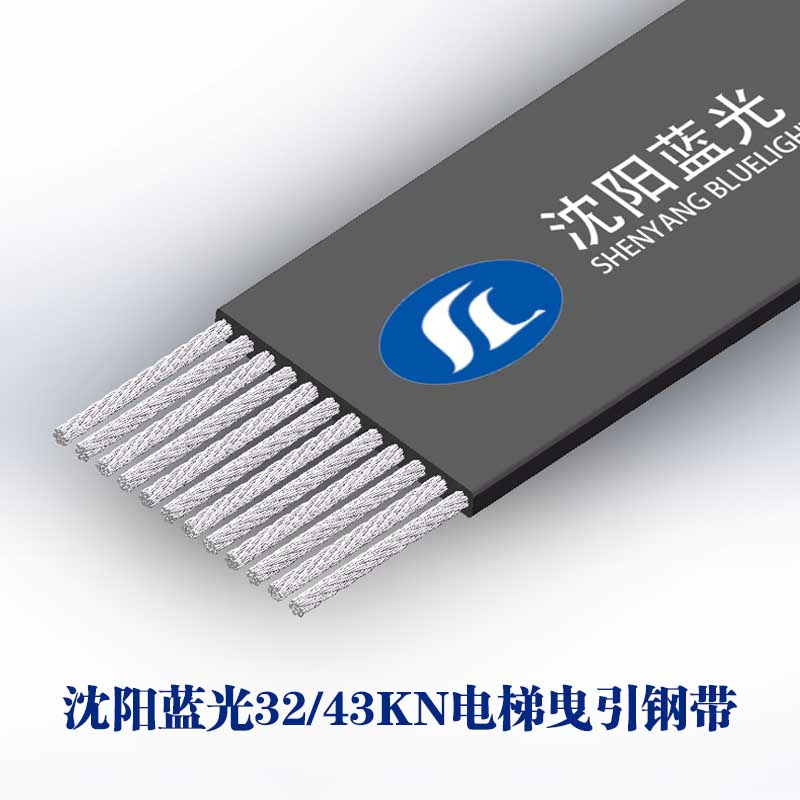

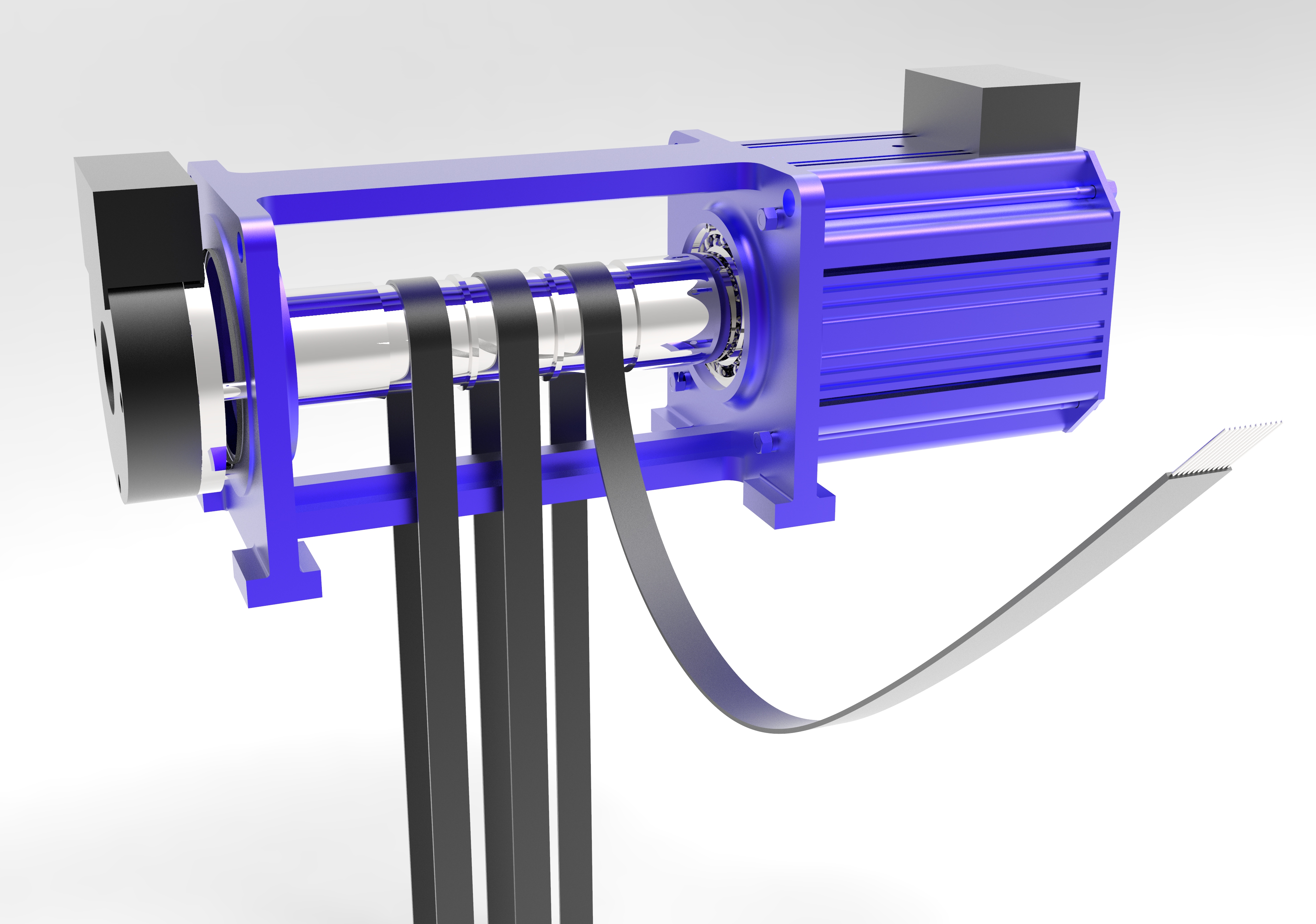

Bluelight Hoisting Belt

- Bluelight

- China

- 15 days

- 2 million meters

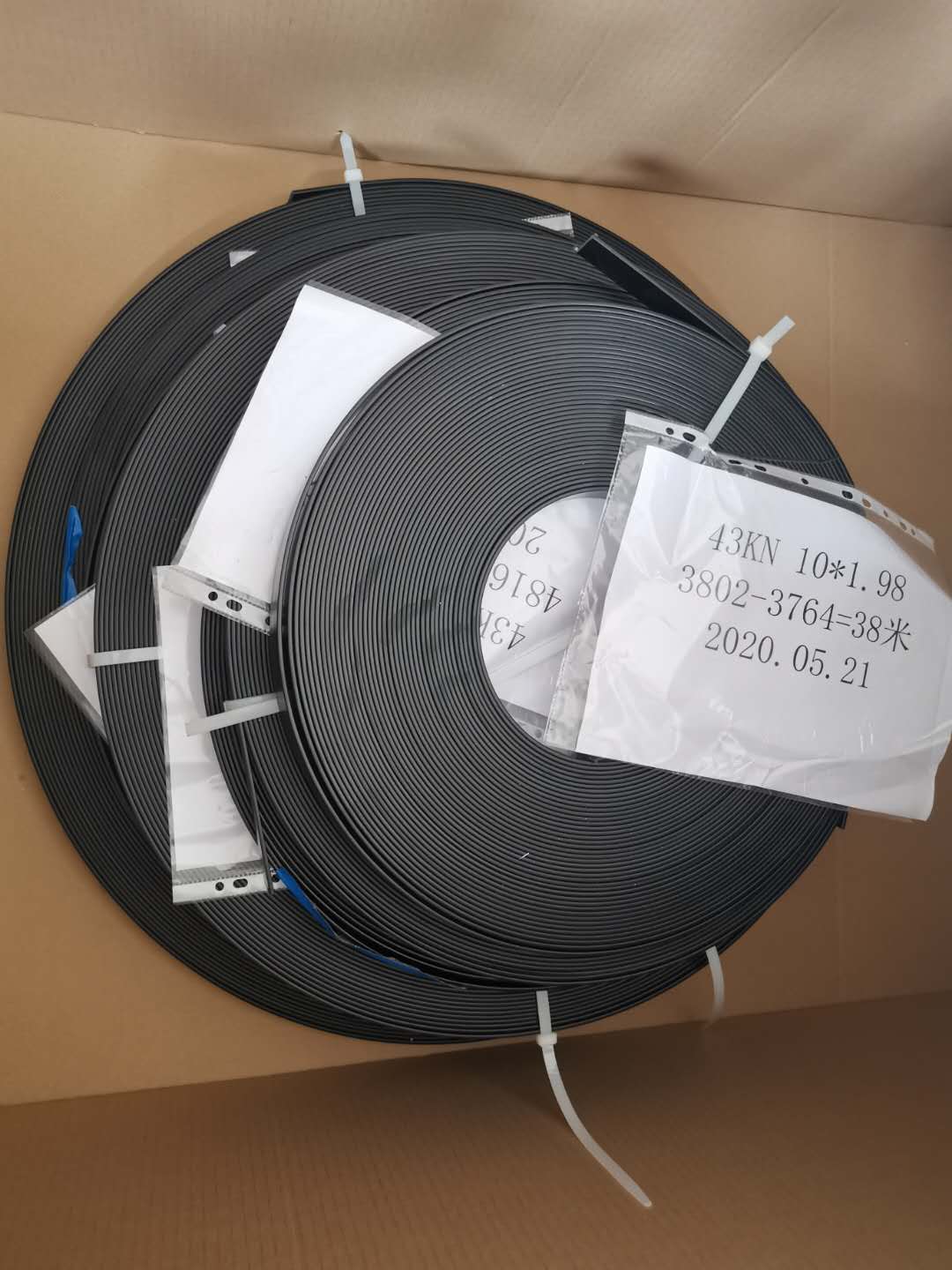

Bluelight has complete production lines from precise galvanized steel rope to elevator traction belt. The annual production capacity of elevator steel belt is 2 million meters. R&D center has invested full sets of testing equipment for elevator traction belt examination and certification, as well supporting product development and customer cooperation.

SYLG-EB

Hoisting Belt for Elevator

Specifications

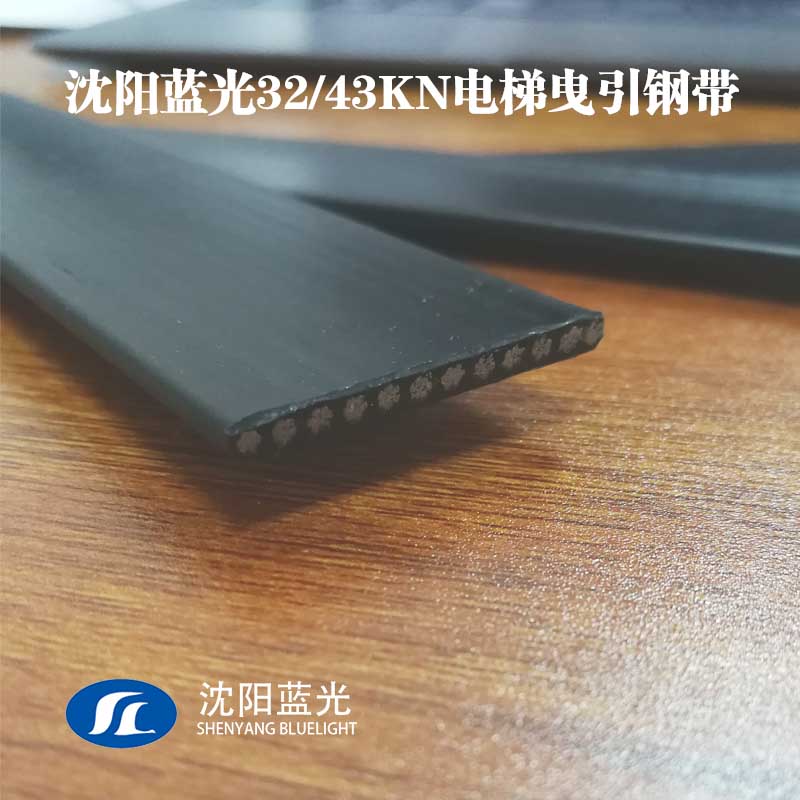

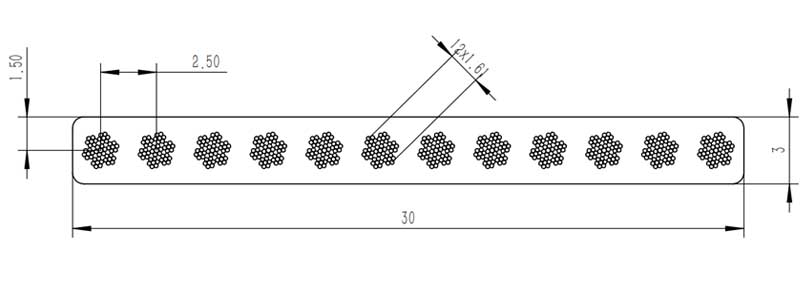

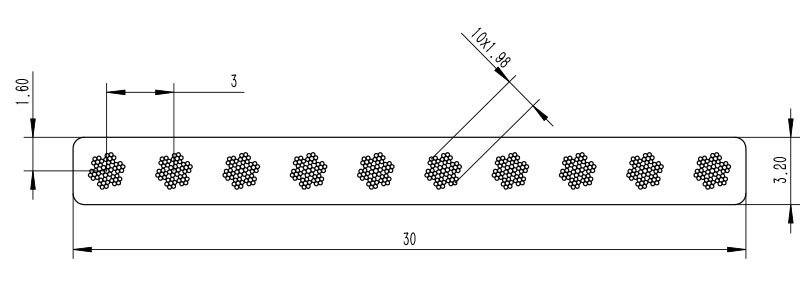

Model | 32kN | 43kN | 50kN | 64kN |

Thickness | 3 | 3.3 | 3.3 | 3.6 |

Width | 30 | 30 | 30 | 36 |

No. of Steel Rope | 12 | 10 | 10 | 12 |

*Please refer to specification list for detail

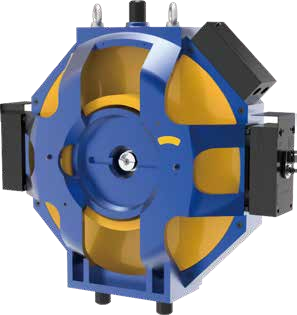

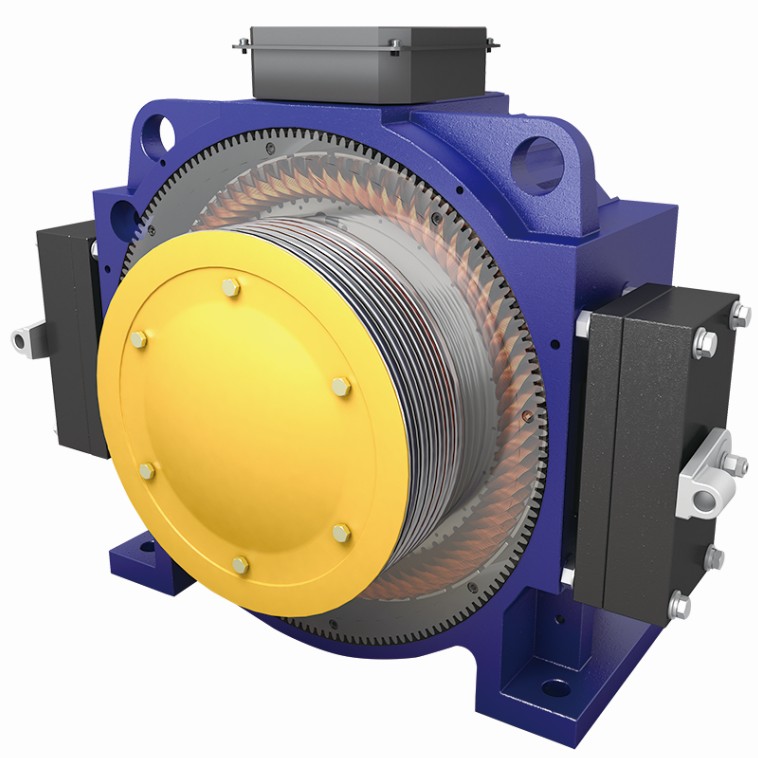

Applications

Number of belt with different model | |||||

Load(kg) | Roping Ratio | 32kN | 43kN | 50kN | 64kN |

630 | 2:1 | 2 | |||

800 | 2:1 | 3 | |||

1000 | 2:1 | 4 | 3 | ||

1250 | 2:1 | 5 | 4 | 3 | |

1600 | 2:1 | 6 | 6 | 4 | 3 |

Calculated by safety factor of 12.

Nominal strength is counted by minimum breaking force with safety margin.

Using 3 belts is the most economic efficiency.

Features

All series produce use BASF Elastogran high hardness TPU, it has excellent mechanical and chemical features.

World class technic to produce high prevision galvanized no joint steel rope, with uniform shaping, high fatigue durability and corrosion resistance.

Great concentration on surface treatment developing, the equivalent friction coefficient is more stable, and capable of handling more complicated working conditions.

Online contour scanning system, real-time monitoring of external dimensions to ensure the same quality of every meter of traction belt.

Traction belt under strict fatigue test during development process. Life time is more than 10 million times bending test.

Unique SITONADHTM surface coating for precise galvanized steel core, the bonding force of the steel core and polyurethane exceeds 8 times the national standard, avoiding the risk of delamination and cracking of the steel belt.