Bluelight Hoisting Belt

Bluelight Hoisting Belt

In one word to describe Bluelight hoisting belt, I believe UNIFORM is its most arresting feature. Bluelight belt is uniform in its quality, no matter from side, length or any other aspects, the belt is consistent in properties such as size, shape and breaking force. Why uniform is so important? Now, let’s see the difference!

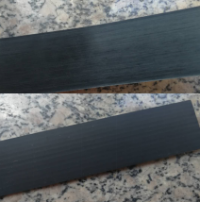

UNIFORM 1: Surface consistency

Other Brand Bluelight Traction Belt

Normally belt made by synchronous belt bonding process, the surface of traction belt that facing the cooling pulley has much lower temperature than the other side. The equivalent friction coefficient of on side is much weaker than the others. Thus, one side looks deep dark but the other looks lighter and reflecting. During installation, users need to pay attention on this, because it can easily cause unbalanced stress and fatigue. Moreover, less quality belt surface is rough, it can cause unstable traction force and belt tear apart. In compare, Bluelight traction belt is made from more advanced process, it has uniform shape, size and features on both sides. By testing, both sides have at equivalent friction coefficient of 0.4.

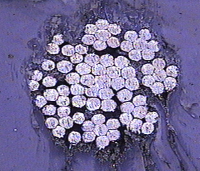

UNIFORM 2: TPU Permeation

Other Brand Bluelight Traction Belt

Using 40 times magnifying scope to check the internal of steel rope core. On the left you can see there are some blank gaps among the steel ropes where no thermoplastic polyurethane fill in. TPU simply surround the ropes but still leave space for moisture to possibly come into. In this case, the cohesion between TPU and steel rope is weak and increases the risk of steel rope corrosion. Compare the photos, Bluelight traction belt has high pressure on the TPU to fill into most of the internal space of steel ropes and let them better immersed to provide more protection.

UNIFORM 3: Steel Ropes Distribution

Other Brand Bluelight Traction Belt

In some belts, the steel ropes are trending toward the cooling pulley side during making process. As a result, the steel ropes are not in the center. So when the belt is bending over time to time, both side will have different strength and hardness, one side the TPU will be easily worn and peeled off. This will increase the rise of breaking. Another problem is the steel ropes are not evenly distributed, ropes have different spaces in between. This can cause steel ropes suffering unbalanced stress, easy to wear and eventually tear apart. Bluelight adopts more difficult process by high pressure squeezing to centralize the steel ropes and equally distribute, make the belt very hard to split.

UNIFORM 4: Steel Ropes and TPU Cohesion

Other Brand Bluelight Traction Belt

The photos show steel ropes after pulled out of belt. On the left, there is no TPU left on the steel. On the right, clearly can see TPU marks stick on the steel. TPU is covering around steel rope to conduct traction force, while steel rope is the sustaining material of skeleton. Therefore, the cohesion of the two is very important for long lasting work. Poor adhesion can easily lead to delamination. Bluelight has very strong cohesion that the pulling force to take the steel rope out of belt is as much as twice of the ordinary belt, prevents belt failure.

Thanks to R&D engineers have focused on advancing the production process to make sure the belt looks perfect, and it actually is, in every directions. So, you can expecting traction belt to have more stable performance!