A Discussion of Methods for Elevator Protection

A Discussion of Methods for Elevator Protection

Even though you meight have heard of elevator accidents. But in reality, elevators are actually the most reliable and safety transportation in the world. Since Elisha Otis cut off his rope during New York World's Fair in 1854, engineers continously design and improve the protection methods to make elevator safer and safer. Now a day, elevators are highly unlikely to cause accidents when under proper maintenance and operations.

Now, let's talk about some mostly used methods for elevator protection.

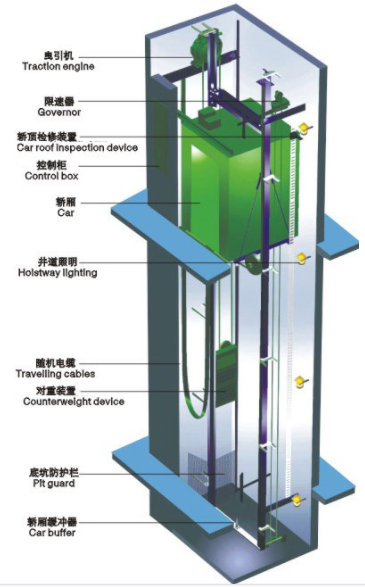

1. First is the machine brake. They are the primary and most important safety protections of elevators. Brakes are closed in normal state, which means under no power, to stop elevator from moving. Commonly brakes are drum type, brick type or disc type. There are 2 to 4 brakes on one machine, sometimes even more. It is required that even with just one brake correctly functional, the machine can be stopped. So, the safety of machine is largerly depended on regular checking on the brakes.

Bluelight control system detects the brake actions as well as two brake arms' movements constantly. Any misbehavior during brake on and off can be detected, and system gives error and stop elevator running. Further more, Bluelight system performs brake force test automatically every midnight when it is not in use. If brake force is insufficient, system stops and gives error note.

2. As you may wonder, what if the steel rope break? This question was first answered by Elisha Otis backing to 1854. When elevator is free falling, the mechanism of speed governor detects overspeed and triggers safety gear. It is usually installed under the cabin, when activated, it clamps on the steel rail and stops the elevator from moving. These days, the safety gear usually just limits the elevator from moving up. Why is that? Because most of the elevators are using traction wheels, on the other end of the traction rope is what we called counterweight. The counterweight is heavier than empty cabin, when in free fall, the counterweight will pull the elevator up. On the other hand, there are multiple steel ropes hanging the cabin, even with one left, it should be strong enough to hang the cabin. So, with regularly checking, it is rare the chance of breaking them all nand let cabin fall, way less possible than it happens in movies.

However, as elevator runs time to time, the steel rope wears out. If it becomes too slipery, the elevator may move unaccordingly to machine controls. To prevent this problem, Bluelight control system is monitoring the rope slid displacement every time it runs. If system detects any time the rope slips out of the allowable range, it stops and gives error. Maintanence staff can also use the rope slip function to perform the test as they want, and change the steel ropes in time.

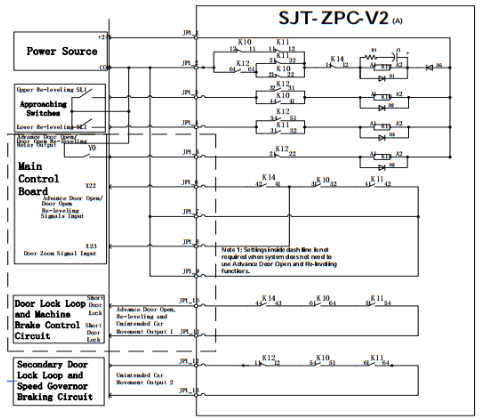

3. Unintended car movement protection or so called UCMP, is wildly required by many standards now, such as EN81-20/50 and China national regulation. One of the risk is when door is open but elevator accidently moves. This could cause shear cut to passenger or staff close the door. UCMP as well as bypass functions are to protect elevator form moving undeliberately or with door open, in case door interlock circuit is been shorted.

System detects car movement from the encoder feedback when elevator is moving out of door zone. UCMP triggers primary mechanism, such as brake for gearless machine, and secondary mechanism, such as rail clamp or rope clipper, to stop elevator further moves.

4. Y-connection contactor is another safety protection for synchronous machine to prevent free falling. You can find out more from my previous article at http://www.chinaelevatorpart.com/news/what-is-a-star-sealed-contactor-kfx

5. Even in extreme condition when all of braking machanisms are not functioning, in this case none of the machine brakes, speed governor, safety gear, Y-connection contactor is working, this is nearly zero possibility to happen in practical, when Bluelight system still can detect car movement after all, systrem will generate torque to the machine and keep elevator wriggling around door zone meanwhile give alarm to let passenger out. After a period of time, system controls the elevator to move up in slow speed, and finally hit the top but in a relative safe speed. So even all braking machnism breaks, control system can still perform the final rescue operation to reduce the damages.

6. Last but not least, to keep elevator in comprehensive maintanence is the most crucial part to ensure elevator safe. Give proper and on time maintanence to an elevator, in reward it will save you from a lot of trobles if you don't.