Elevator Group Control Board

- Bluelight

- China

- 15 days

- 100000 unit / year

1. Only required when Elevator between 3 to 8 units to make goup control more efficient.

2. CAN-BUS communication

3. Stops<64

Elevator Group Control Board

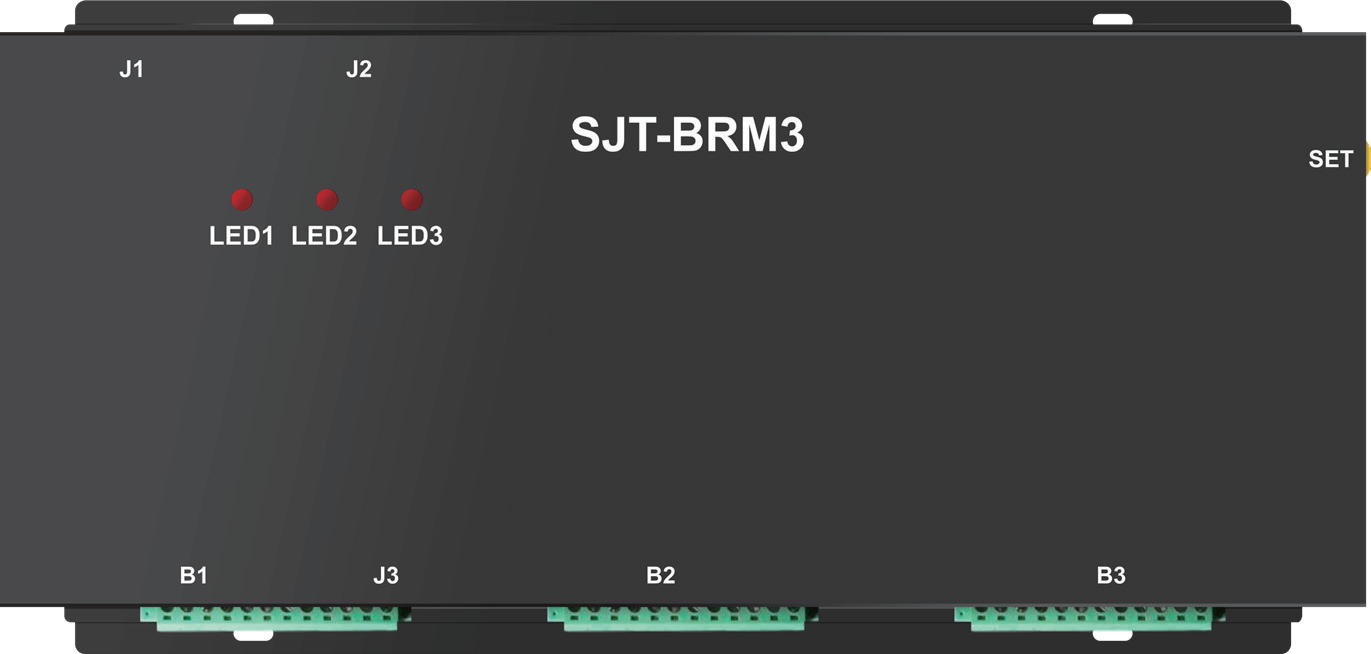

Model: BL2000-QKB

Features

1. Simple configuration: only one group control board required and CAN-BUS communications.

2. Max. number of elevators: 8 units

3. Stops: < 64

4. Make elevator group control more efficiently.

a. Peak Hour Mode: fuilfill the elevator demand in peak hour for public places

such as office buildings.

b. Balanced Running Mode: optimal elevator allocation to minimize users' waiting time,

ElevatorS response fast and appropriate.

c. Idle Running Mode: evenly distribute elevators at designated doors during idle

time to minimize the reaction time of answering landing calls.

d. Automatic Removal of Reluctant Elevators: Ensure fast respone of landing calls.

Bluelight Partners

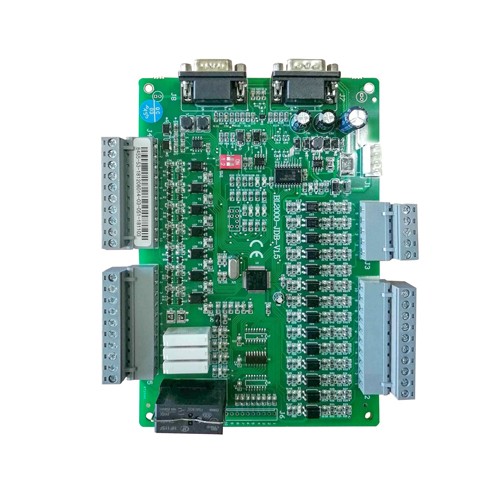

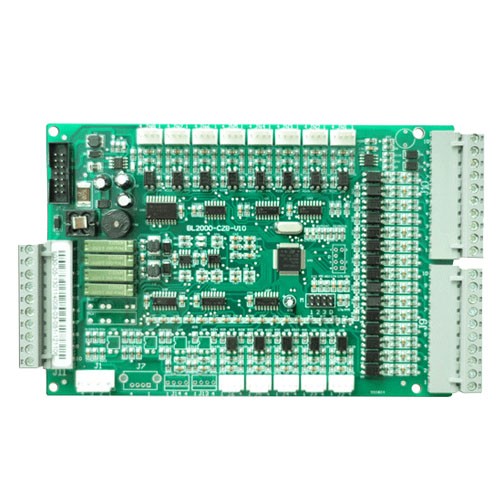

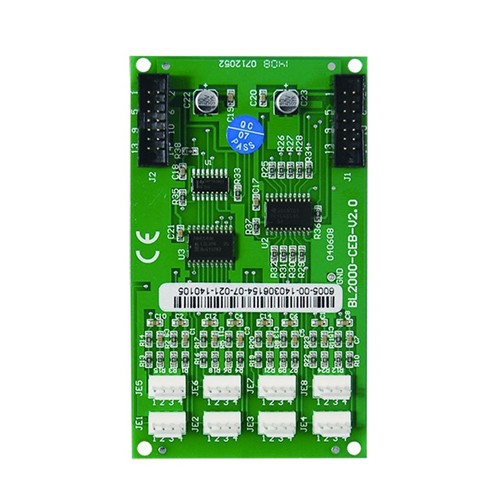

Other products you would be interested (Please check "Product" to find more details)

Bluelight Advantages

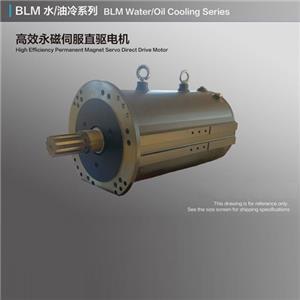

Founded in 1989, a technology-based company with the highest technical strength. The only manufacturer in China to produce both control system and PM traction machine

Strong R&D team customizes products to meet your market requirement and increase added value of your products.

Full range of control system products, covers elevator integrated controller, integrated control cabinet, control board, COP, LOP, ARD, Electrical brake releasing device and monitoring system, etc.

Strict quality control, 100% inspection before delivery, saves maintenance cost for you.

Professional team with more than 20 years of export trade experience provides you the most professional guidance and advice.

Comprehensive certificates, such as CE, KTL, etc.

24-hour professional English technical consultant, free after-sales service and technical training.

Three factories (locates in Shenyang, Suzhou, Foshan) have sufficient production capacity, guaranteed delivery time and convenient port delivery to save cost for you.